Hi welcome to my 1964 VW Type 2 split screen campervan restoration blog. This will be a record of the vans restoration, and hopfully share infomation about bringing a splitty back to life.

Still on going

Machined front caliper mounts

Van Restoration Relocation

Haven't had much time to get on with the panel repairs because the restoration has had to be relocated, I was able to find a nice big double garage with power and water, this means I'm now able to work on the side of the van and not just the front and the back. Amazingly, through a door in the back of the garage I found, tucked behind some bushes and an over grown garden a house that also had electricity and running water. My girlfriend was happy to stay there while I get on with the rest of the restoration.

Haven't had much time to get on with the panel repairs because the restoration has had to be relocated, I was able to find a nice big double garage with power and water, this means I'm now able to work on the side of the van and not just the front and the back. Amazingly, through a door in the back of the garage I found, tucked behind some bushes and an over grown garden a house that also had electricity and running water. My girlfriend was happy to stay there while I get on with the rest of the restoration. When I originally found the garage and measured it up for the fit, there was loads of room to work, but it was very close on height. I thought I may be pushing it in and out of the garage with flat tires, or having to start another project of raising the roof, and I don’t think I'll be able to keep a roof rack on for long.

When I originally found the garage and measured it up for the fit, there was loads of room to work, but it was very close on height. I thought I may be pushing it in and out of the garage with flat tires, or having to start another project of raising the roof, and I don’t think I'll be able to keep a roof rack on for long.The vans trip to its new home went smooth, A few curtains twitch as a rusty heap was unloaded from the flat bed on to the street, Then, what I forgot to do was measure the width of the access lane to the garage. Pushing a van enthusiastically down an ally when you have 6in or less clearance either side and you don't have any breaks is a bit scary.

Having all this room In the garage didn't last long, to accompany the van came all the VW parts I’ve been hording for the last 10+ years (just in case I might just need that old rusty part), gear boxes, engines, tones of engine tin wear, exhausts, front beams and boxes of all the smaller bits. It's going to take some time to clear away the unwanted parts, and sort out a working garage, but in the end it should make getting the van back on the road so much more enjoyable.

Left "A" pillar and cab floor

Cab floor and door seal carrier repair

The bus also got it's first bit of sun for the summer.

Porsche brake conversion Pt3

Porsche brake conversion Pt2

Front Valance Pt3

I received the new lower front panel (which I specially requested without the cut out for the nose and longer at the ends so I can fold it over like the original.) Rather than butt weld this panel I joggled a small lip on the repair panel to sit inside the original one. I ground a ton of filler off the front panel so I could ensure the repair panel was straight, although a bit tricky around the nose; using some fabricating magnets and clamps the panel fitted OK.

Eager to get the panel on I started tacking it together, then double checking the fit before I went welding crazy I noticed that the joggle at the left corner end of the panel was overlapping to much, and causing the curve of the panels not to sit flush. Access to the back of this panel is very awkward because of the front light bowl and inner kick panel, this ruled out any fabrication from the back. So I painstakingly cut the joggle off from the front with a cut down junior hacksaw clamped in a pair of pliers. This did the job of letting the pannels sit flush, and then with the magnets in place I continued to tack it all together.

Learning from my cock up with warping the dog leg panel I spaced out the weld points and spot welded the a seam between the two panels with only a second spent on each weld, but still the original part of the panel had a slight ripple along its curve. Not sure if I’m being to particular about my work or still have a lot to learn but I'm determined to get it right. So I guess Ill rely on the paint prep to get rid of any imperfections (filler).

front door hindge replacement

Porsche brake conversion

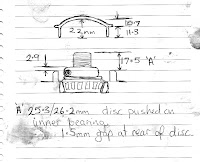

porsche-brake-conversions technical info

After having a bit of a break from welding up the van, I spent a few late nights on the net working out the best option for the wheel and brake set up that I'd like. About 10 years ago I bought a set of 15"x6" Porsche Fusch alloys, I later found out from a friend that the guy I bought the wheels from had said they couldn’t be fitted to a van. Well, with that in mind, I saw it as a challenge.

After reading a few split screen van club forum discussions and a few tips from members, I’ve started by getting hold of a set of front and back Porsche 944 hubs (non turbo) and rear swing arms. This will allow me the choice off aluminium arms or the VW type 3 set up I have had laying in my garage. But that decisions for later.

After reading a few split screen van club forum discussions and a few tips from members, I’ve started by getting hold of a set of front and back Porsche 944 hubs (non turbo) and rear swing arms. This will allow me the choice off aluminium arms or the VW type 3 set up I have had laying in my garage. But that decisions for later.

- Split 1964 king and link pin drums.

- Bay 1968 ball joint drums.

- Bay 1971-ish small stud Pattern discs brakes.