Taking a break from all the welding and body work, I managed to drag my mate Tim from working on his own van to spend the day removing my rear end and measuring up for the sexier back side. On the VW not my own body. He's not an amateur surgeon. Just to clear that up...

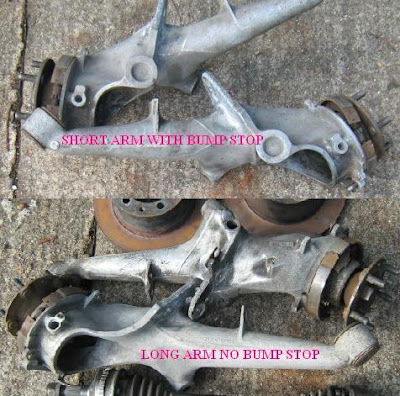

This is a Porsche 924s (not a 944 as stated in the title but I think they are the same) rear axle that I ordered from Porsche Apart and it arrived in a box as wide as my garage, doing a little VW to Porsche IRS conversion research online I've found that there are two types of 944 aluminium A arms, one shorter than the other, I hope I have the right one. I've also had a few comments that this can't be done so lets see if they're right.

This is a Porsche 924s (not a 944 as stated in the title but I think they are the same) rear axle that I ordered from Porsche Apart and it arrived in a box as wide as my garage, doing a little VW to Porsche IRS conversion research online I've found that there are two types of 944 aluminium A arms, one shorter than the other, I hope I have the right one. I've also had a few comments that this can't be done so lets see if they're right.

I've played with the hubs and discs previously (usually when I'm alone in the house) but it was now time to get the serious stuff sorted out. So a quick spray of penetrating oil on all the bolts and the original gearbox and reduction boxes pop out after 40 years with no bother.

Here are the A arm mounting points on the 924s beam, this beam is the same diameter as the bus one at 90mm. I may try and use these mounts if I can't work out how to make a fresh pair.

The mornings' work gave us the measurements we needed to calculate the size and shape of the A arm and most importantly if they would fit. I've drawn up a plan of the measurements to get an idea of how things are going to fit (the arm on the drawing is a bit fat). The Porsche axle wheel offset including discs worked out to be 1497mm across, the Bus axle with the original reduction boxes and drums came up as 1445mm across. To keep the outer wheel rim in the original position under the arch and using wheels with an extra 40mm offset means I'll need to locate the A arm mounting points 46mm closer to the center line.

The mornings' work gave us the measurements we needed to calculate the size and shape of the A arm and most importantly if they would fit. I've drawn up a plan of the measurements to get an idea of how things are going to fit (the arm on the drawing is a bit fat). The Porsche axle wheel offset including discs worked out to be 1497mm across, the Bus axle with the original reduction boxes and drums came up as 1445mm across. To keep the outer wheel rim in the original position under the arch and using wheels with an extra 40mm offset means I'll need to locate the A arm mounting points 46mm closer to the center line. I've also stolen a couple of photos from the SSVC 'For Sale' forum of a 944 rear end and edited them to show the comparison of the different length arms below. Please don't sue me if you hold the copyright of these pics. The longer arms have no bump stop molded in the arm and a longer reach from the spring plate mount.

I've also stolen a couple of photos from the SSVC 'For Sale' forum of a 944 rear end and edited them to show the comparison of the different length arms below. Please don't sue me if you hold the copyright of these pics. The longer arms have no bump stop molded in the arm and a longer reach from the spring plate mount.